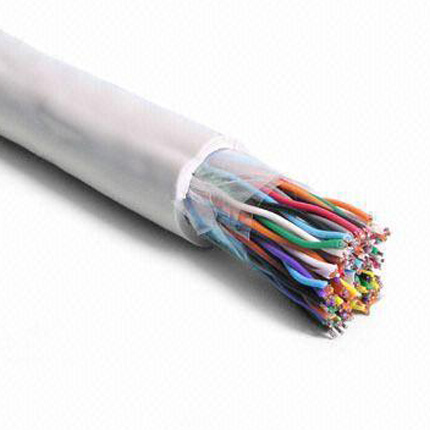

Polyethylene exhibits:

- Excellent electrical insulating properties

- Good stable mechanical properties

- Resistance to chemical attacks

All these properties have rendered polyethylene an efffective and important insulating material in the manufacture of low volage cables. Polyethylene is however not suitable for use under high temperatures. This is mainly due to the molecular structure of the polyethylene polymer which is made up of ethylene monomers loosely held together by weak molecular bonds. This (and other reasons) led to the development of associated compounds, such as

Linear low-density polyethylene (LLDPE) - It is a substantially linear polymer (polyethylene), with significant numbers of short branches, commonly made by copolymerization of ethylene with longer-chain olefins. Linear low-density polyethylene differs structurally from conventional low-density polyethylene (LDPE) because of the absence of long chain branching. The linearity of LLDPE results from the different manufacturing processes of LLDPE and LDPE. In general, LLDPE is produced at lower temperatures and pressures by copolymerization of ethylene and such higher alpha-olefins as butene, hexene, or octene. The copolymerization process produces a LLDPE polymer that has a narrower molecular weight distribution than conventional LDPE and in combination with the linear structure, significantly different rheological properties.

LLDPE has penetrated almost all traditional markets for polyethylene; it is used for plastic bags and sheets (where it allows using lower thickness than comparable LDPE), plastic wrap, stretch wrap, pouches, toys, covers, lids, pipes, buckets and containers, covering of cables, geomembranes and mainly flexible tubing.