Polyethylene exhibits:

- Excellent electrical insulating properties

- Good stable mechanical properties

- Resistance to chemical attacks

All these properties have rendered polyethylene an efffective and important insulating material in the manufacture of low volage cables. Polyethylene is however not suitable for use under high temperatures. This is mainly due to the molecular structure of the polyethylene polymer which is made up of ethylene monomers loosely held together by weak molecular bonds. This (and other reasons) led to the development of associated compounds, such as

Low-density polyethylene (LDPE) - It is a thermoplastic made from the monomer ethylene. LDPE continues to be an important plastic grade. In 2013 the worldwide LDPE market reached a volume of about US$33 billion. It was the first grade of polyethylene, produced in 1933. LDPE is defined by a density range of 0.910–0.940 g/cm3. It is not reactive at room temperatures, except by strong oxidizing agents, and some solvents cause swelling. It can withstand temperatures of 80 °C continuously and 95 °C for a short time. Made in translucent or opaque variations, it is quite flexible, and tough but breakable.

It has excellent resistance having no attack/no chemical reaction to dilute and concentrated acids, alcohols, bases and esters. It has good resistance to aldehydes, ketones and vegetable oils. Limited resistance to aliphatic and aromatic hydrocarbons, mineral oils, and oxidizing agents. Poor resistance, and not recommended for use with halogenated hydrocarbons.

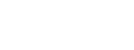

For Communication Cables

Intended for use in sheathing and jacketing of both dry & jelly filled communication cable.